|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

Gluing nylon cloth to wood with plastic glue

|

|

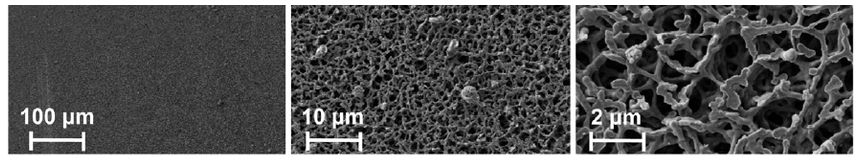

NOTE: The rubberized side of the cloth gets glued to the wood, not the nylon side. There's a video at YouTube that might be helpful. It demonstrates a pneumatic being covered with thin nylon cloth and plastic glue at about minute 29 of the video. https://www.youtube.com/watch?v=02LcoEv_ArY We also have a webpage that lists the glue specs and shows how to apply the glue - click here. I'll try to explain one of the problems with nylon cloth and plastic glue that has come up more than a few times. Plastic glue dries by evaporation. That means it needs air to fully dry. So, if you have a piece of wood that's air-tight and cloth that's air tight, how does the air get into the glued surface to dry? Hmmmmmm...? As you might have noticed in the above video, he uses an iron to heat the cloth and glue. This does two things. One, it thins out the glue between the cloth and the wood. That's important because with more glue, it will take longer to dry. Two, it speeds up the evaporation process. What's not obvious in the video is that the wood has been sanded so the surface is a little rough. This is important because the roughness of the wood provides channels so air can get to the 'inside' portions of the gluing surface. As it was explained to me, 'That means the microscopic and macroscopic terrain of the two surfaces creates the tightness of the bond. Wood pores, tear-outs, rough sanding marks, scraping lines, etc., all strengthen the bond....' As the glue dries, it also creates a microscopic lattice network through which air molecules can move, which facilitates the complete drying of the glue. Here's an image taken with an electron microscope.

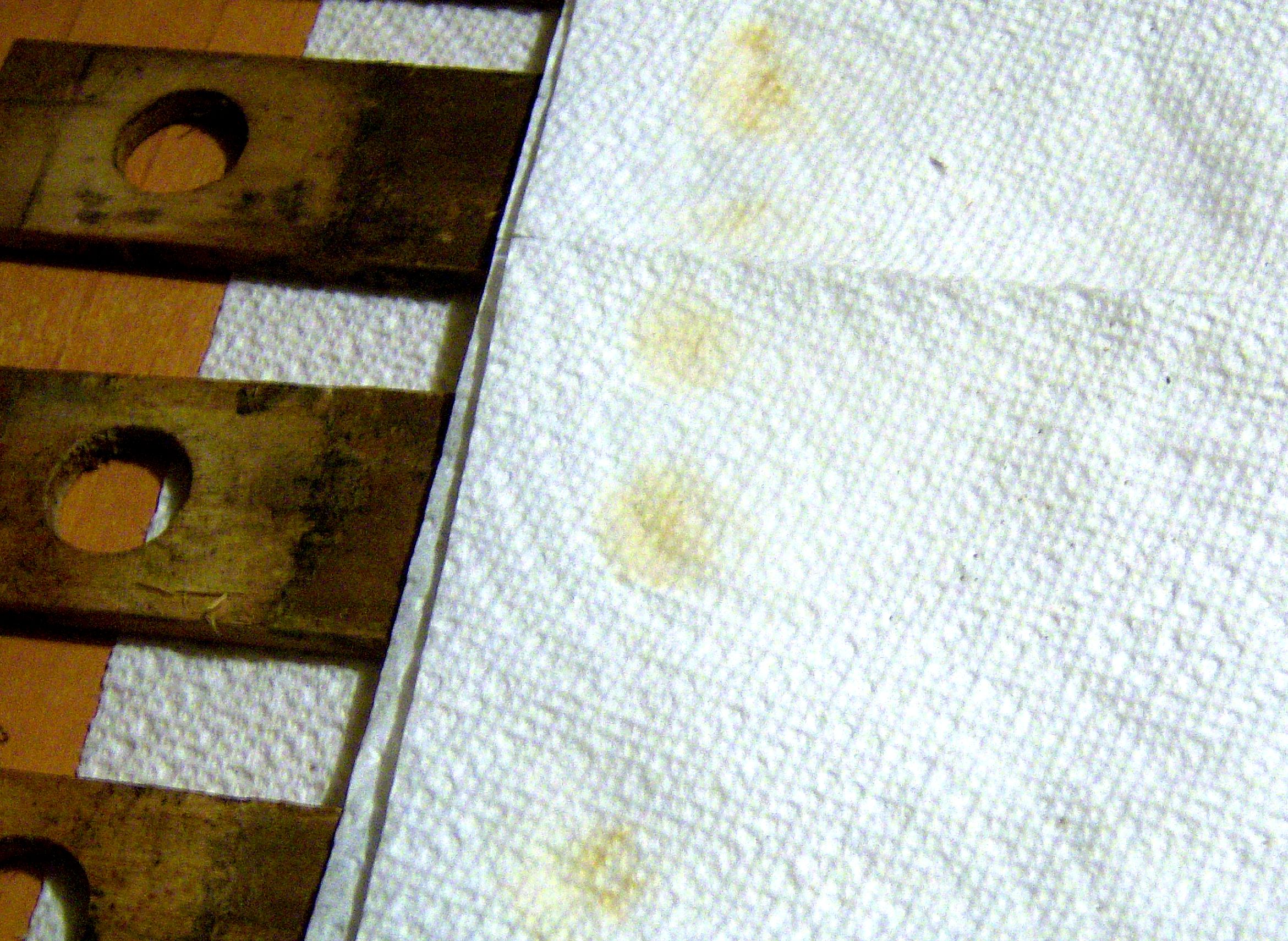

As it was explained to me, 'Any glue which relies on the evaporation and absorption of moisture away from the joint to set and to eventually dry creates a "lacy pattern" in its joint structure, through which air is able to flow unless the joint is securely clamped for 24 hours.' Another thing that's not completely explain is how long he lets the pieces dry before going on to the next step. He does say 'a few hours', but it's hard to know exactly how long that was.... In the video segment below, I let the glue dry for 1-1/4 hours (75 minutes). When I use plastic glue to glue nylon cloth to a bellows, I do only one side of the bellows at a time, and I wait until I can see that the 'squeeze' (the glue that squeezes out when the edge is pressed onto a flat surface) has become clear (no white or milkiness left). Even then, the glue isn't completely dry. So, after I've finished covering the open end of the bellows and the two sides, I let the glue dry overnight before gluing the hinged end (with the bellows collapsed). After that, I let the glue dry another 24 hours. Even after all of that, the cloth can be pulled off of the bellows without a great degree of effort. However, that is to be expected because the nylon cloth is so much stronger than the glue. Fortunately, the glue bond is more than sufficient to keep the cloth permanently secured to the wood and it creates an almost perfectly air tight seal. Now, if we were using pressure instead of vacuum, there might be a problem. Or, if the bellows is spring-loaded there might be a problem. I did not investigate what's known as 'creep' when creating this webpage because the focus was on using thin nylon cloth and plastic glue when covering striker pneumatics. Another thing: If the gluing surfaces of the wood are well sealed with old animal hide glue, it's very difficult for the air to get into the inner portions of the gluing surface. This slows the drying process substantially. All I can say to that is, run some tests, or rough up the surface so the air can get into the inner surfaces. Also, the moisture content of the wood can be a problem. An easy way to test for moisture in the wood is to take a piece and put it on a paper towel and cook it in a microwave for 45 seconds. If it's dry, the paper towel will be dry after the test. If not, you'll see the moisture on the towel. The wood in this picture felt perfectly dry, but here in New Jersey in the middle of Summer, the humidity is usually around 70%. After just 45 seconds in the microwave, it was obvious that the wood was not dry.

Spots on the paper are moisture that came out of the end grain of the wood. One of the tests that I used years ago to test the glue bond of hide glue was to apply 15-20 psi of pressure to a bellow. If the cloth didn't blow off or a seal fail, the bond was secure. What's interesting to note is that 15 psi of air pressure is equivalent to 415 inches of water vacuum, and it's totally unreasonable to think at any player piano will ever be operated at 400+ inches of water vacuum. In fact, the largest grands that were used to play concerts, with the Duo-Art and Ampico reproducing player systems, never used more than 90 inches of vacuum. That's equivalent to only 3.25 psi of air pressure. So, in the video below, I'm starting at 5 psi to see how much pressure it will take to cause the plastic glue seal to fail.

What this test proved rather conclusively is that stretching the cloth at an angle away from the edge of the wood (where it is glued to the wood) is what caused the seal to fail. That situation never occurs with striker pneumatics in a player piano because the vacuum is always pulling the cloth inwards, not blowing the cloth outwards. Also, it's important to note that 8 psi of air pressure is equivalent to about 220 inches of water vacuum. The average player piano works on less than 30 inches of water vacuum, which is equivalent to about one pound per square inch (1 psi) of air pressure . The point of all of this is not to say that plastic glue doesn't work well. In fact, plastic glue is the best glue for gluing nylon cloth to wood because it makes the strongest mechanical bond of all similar adhesives. But, unlike hide glue, plastic glue does not make a chemical bond. Therefore, it doesn't make as strong of a bond as hide glue. However, plastic glue does more than an adequate job, and it can be trusted to last for decades if certain precautions, as explained earlier, are taken during the gluing process.

As noted in the video at YouTube: "I tested three types of thin pneumatic cloth. There were six tests in all. Only two of them are worth reporting. The first one is the old traditional 0.008" cotton/rubber cloth that was used for decades. The second is a 0.0045" synthetic/rubber cloth sold by Herzog in Germany. In both cases, the cloth side was glued to the wood with hide glue. The results surprised me..." BTW, gluing the cloth side of striker pneumatic cloth to the wood is not the conventional way the job is done. Normally, the rubber side is glued to the wood. This experiment was done to see if the hide glue/cotton cloth stuck better than the hide glue/synthetic cloth.

|

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |