|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

|

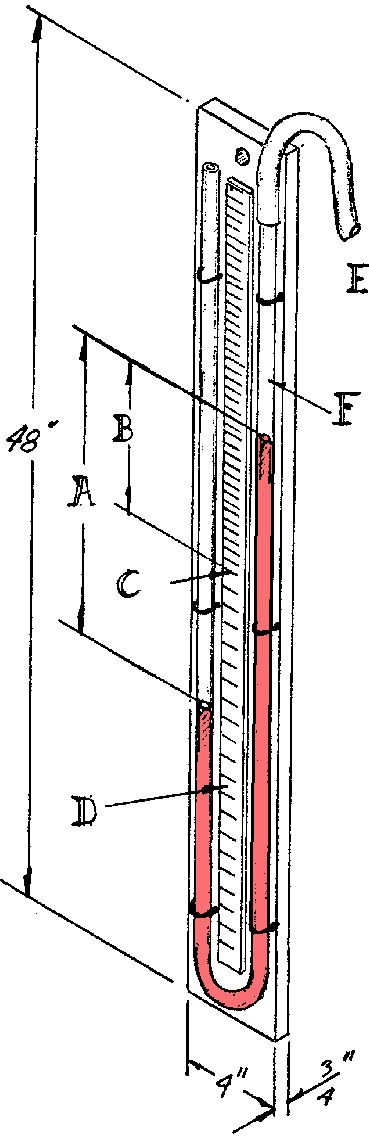

VACUUM GAUGE

NOTE: This gauge can safely measure up to 45 inches of water vacuum. F is either clear plastic or glass tubing, with an inside diameter of at least 3/8 inch. It is formed to a U-shape and fastened to the board by any convenient means; if glass is used a rubber tube can be used to form the U at the bottom. D is a yardstick or other scale marked off in inches. One end of the tubing is left open to the atmosphere, and the other is connected to a piece of rubber tubing, as at E, which is used to connect to the vacuum source being tested. The tubing is filled to its midpoint C with water. If it is colored with ordinary vegetable coloring liquid, found in most household kitchens, it is easier to read. When a vacuum is introduced at E, the water will rise in that side of the tube, and the total amount of vacuum is indicated by the number of inches between the tops of the water columns, as A. This will be the difference between the numbers of inches on the scale D. A direct-reading gauge can be made by marking a scale with half-inches indicated as inches, and making sure that the 0 inch mark always coincides with the level of the water at rest, either by making the scale adjustable, or by making sure the amount of water is such that it always comes to the 0 point at rest. Such an arrangement is easier to work with, as the readings can always be made directly such as at B. Use the fact that one inch of water in a water column is equal to 0.036 pounds per square inch of pressure; this is your conversion factor. From the example, 10 inches of water (10" WC) is equivalent to 0.36 pounds of pressure (0.36 psi). Looking at it another way, a player piano that's in decent shape will play music loudly on about ONE pound of air pressure (or 27.7" WC). Here's another formula: 1 inch of mercury = 1.132 feet of water = 13.58 inches of water = 0.491 pound per square inch. |

|

If you have a closed system, any closed system, and you apply a known level of negative air pressure, the difference between the known level and the level you read on the gauge, that's connected to that system to monitor the pressure, indicates the amount of leakage within that system. Below are a few different scenarios: If you have a pump that produces 30" of vacuum and you connect it to a stack with all of the note holes closed except the one that's connected to the vacuum gauge, and the gauge reads 20", you have 10 inches of leakage within the stack. These are called static losses. If you connect the gauge to a pumper assembly with all of the ports closed except the one to which the gauge is connected, and you pump the pedals until the gauge reads 30" and then stop pumping, the number of seconds it takes for the reading to go down to zero indicates leakage in the assembly in inches per second. These are also called static losses. Obviously, in a perfect world, the only vacuum leakage you should have within any component in a player system is the leakage required to operate that system. In other words, every time a note plays, a certain amount of air enters the system during the time it takes for the valve to go from the 'off' position to the 'on' position. At the same time, a certain amount of air is entering the system while the perforation in the trackerbar is open because of the bleed. When the perforation passes, a certain amount of air enters the system as the valve changes state from 'on' to 'off'. These are called operational losses. Looking at all of this from a different point of view, a well-rebuilt player system should be able to operate on 5"-7" of vacuum pressure. If the system requires 15" to operate, the efficiency of the system is between 33% and 50%. Most rebuilders shoot for an efficiency of around 90%-95% -which is realistic in the vast majority of player systems. Also, vacuum gauges are used to regulate the expression devices in reproducing and expression systems like Duo-Art, Ampico, Recordo, etc., etc. In such cases, the desired vacuum levels are established by the manufacturer. So, the piano should play very softly at 5"-6" and very loudly at 26"-30". Also, the gauge is used when regulating a spill valve -like the kind found in a rotary vacuum pump. The gauge can also be used to measure fluctuations as a system is operating. Say, for example, you connect the gauge to a closed foot pump assembly and you start pumping. But when you pump the right pedal the reading goes up to 15" and when you pump the left pedal the reading goes up to 20". That would be an indication that there's leakage in the flap valves and/or the bellows cloth in the right exhauster bellow. The view this video at YouTube -click here. The view this video at YouTube -click here.

Manometer setup for testing various devices The graphic above demonstrates how to setup the manometer and a vacuum pump to test for both 'static' and 'operational' losses in any pneumatic component. Before beginning the test, seal the hose that will be connected to the component and, while watching the manometer, use the throttle to adjust the vacuum level to the desired pressure. Then unseal the hose and connect it to the component. The difference between the vacuum level that was initially set and the level as read on the manometer represents that static loss in the component. The check for the operational losses, activate and deactivate the component. To determine the source of the losses, see the page on finding leaks -click here |

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |