|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

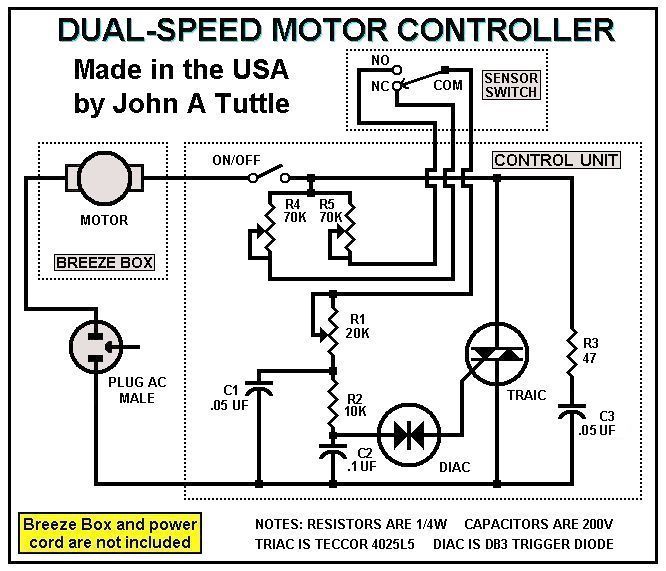

HISTORY: Since the 'Dual-Speed' controller came on the market around 1960, it's been what's referred to as "interactive". That means that the lowest speed of the pump motor gets established by the Rewind Speed Control setting. Below is a little graphic which shows an example of the old operating principle.  The Speed of Rewind is represented by the space where the word 'Rewind' is written. The Rewind Speed Control can be set to anywhere from '0%' to '100%'. Typically, it is set somewhere between 20%-35%, depending on how fast the user wants the music roll to rewind. Then, once the Play/Rewind lever is moved to the Play position, a microswitch tells the controller to add another leg to the control circuitry. (See the Old Schematic.) Once that happens, the Volume Control takes control of the circuitry, and the controller can be turned up to its maximum capability. Typically, the control is turned up to somewhere between 40%-60%, depending on how loud the user wants to music to play. HOWEVER, the volume of the music could NOT be turned any LOWER than the setting of the Rewind Speed Control. That's why it was referred to as an 'interactive' controller. While the above arrangement was satisfactory for most player pianos, it didn't work well in others. The most notable being the Gulbransen player mechanism, which typically required more vacuum during the Rewind cycle than during the Play cycle. Also, players that had been expertly restored often required a little more vacuum at the beginning of the Rewind cycle because of the increase in the load on the air motor -caused by gearing in the transmission, the weight of the paper on the take-up spool, and the rewind brake. The next problem had to do with the what technicians call 'limiting' or 'choking'. In fact, the current flowing through the triac increases as the speed of the motor increases. Conversely, if the voltage being applied to the motor is insufficient to get the motor to start turning (called 'idle'), the windings can overheat and possibly get hot enough to start a fire. So, to avoid the situation where the triac might become overheated and burn out, the regulating portion of the circuit was designed such that the motor would never operate at more than about 70% of its maximum speed. To avoid potential 'idle' problem, the circuitry was also designed such that the motor would keep turning even if the controls were turned down to minimum. The final problem had to do with the "one size fits all" characteristic of the controller. It was designed to be compatible with whatever make and model of vacuum pump motor the company was installing in the breeze box at the time. As a result, the controller was unpredictable when used with older breeze boxes sold by the same company, pump boxes that were made by other companies, and boxes that were 'home-made'. .Cost: $280.00

NEW FEATURES: Our newest controller, which went into production in July 2018, addresses all of the above problems. First, the portions of the circuitry that control the Play and Rewind speeds of the motor are now completely 'independent'. So, whether the player mechanism is in the Rewind or the Play mode, the speed of the vacuum pump motor can be set anywhere from minimum (or about 1" WC) to maximum, at the user's discretion. Secondly, "choking' has been reduced to approximately 15% (varies slightly with different motors). So, if the vacuum pump motor is capable of producing 90" WC of vacuum, the controller can control the speed of the motor from 1" to 75+" WC. (This claim is made by no other manufacturer of player piano vacuum pump systems.) Third, to insure that the triac never overheats (unless it's purposely shorted out), a large heat sink has been installed and the amperage rating of the triac has been increased from 8 amps to 15 amps. Fourth, the circuit is designed such that when the controls are turned to minimum, the gate that controls the traic is not closed. So, the motor continues to spin at a low RPM. To make this feature possible, an on-board trim pot was installed that gives the user the ability to adjust the controller to their particular motor. (No other controller offers this feature.) This adjustment is located on the underside of the controller. So, the adjustment can only be changed when the controller is removed from the location where it's mounted. (NOTE: The new controller, that is part of our vacuum pump kit, does not have the 'user accessible' adjustment. The trim pot is adjusted to the correct setting when the pump kit is tested, and it should not be changed.) Lastly, no expense has been spared in the selection of components. All of the resistors have the gold band and they are operated at less than 1/2 of their rated wattage. All of the capacitors are the well-known and highly respected Sprague 'Orange Drop' brand. As mentioned previously, the current handling capability of the triac has been doubled, which gives it the ability to handle the demands of older motors. We're so confident that our controller will last that it has a Two-Year Guarantee, and we'll reimburse you the cost of return shipping (within the U.S.). If it fails for any reason (short of abuse or a lightening strike) after the two years, send it back and we'll fix it for free. (Does not include the shipping costs.) NOTE: If you are buying this controller to replace one of the old ones that were made by Player Piano Co. (PPCo), it is STRONGLY RECOMMENDED that you let us know the maximum vacuum level of your vacuum pump motor. This is because PPCo used many different motors in their pump boxes and the circuitry in the controller was adapted to suit that motor. If you can't determine the vacuum level, send us the motor and we'll test it for free. That way we can adapt the circuitry in the controller for maximum efficiency. FYI, we CANNOT guarantee that the controller will work well unless we know the vacuum level of the existing pump. |

| Player Piano Reference Materials - Click Here |

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |