|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

|

These pictures were supplied to Player-Care.com by Tim Geinert.

The effort here is to increase the amount of available information about this player system. If you have any additional pictures or information, please send them to John A Tuttle.

Tim Geinert

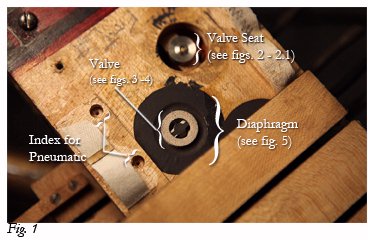

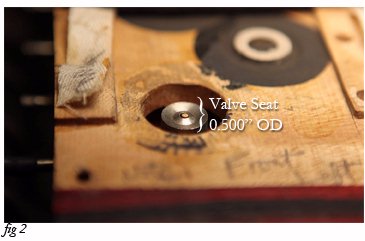

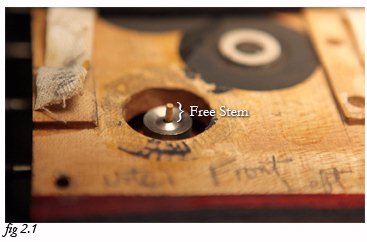

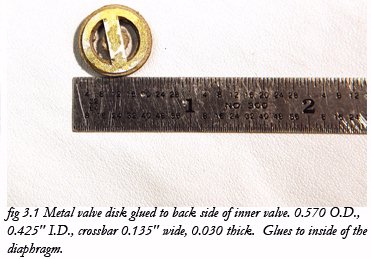

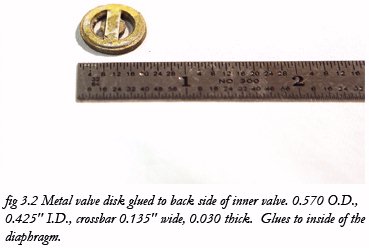

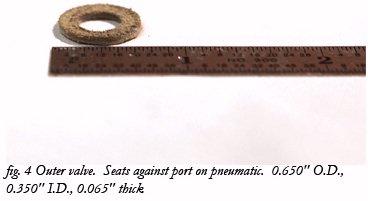

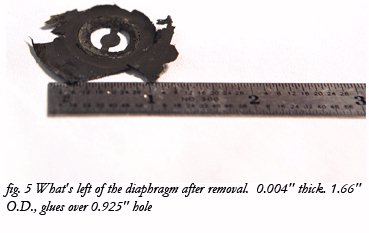

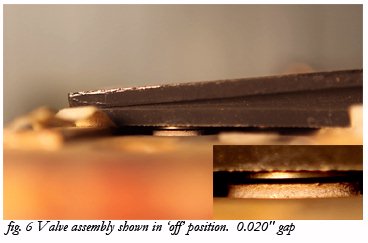

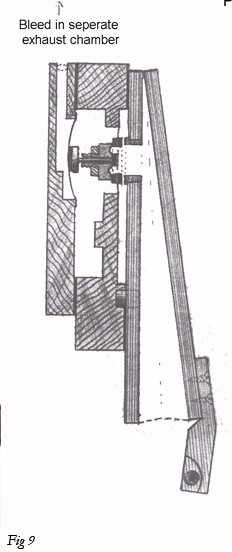

Unlike any system I have ever seen, the Kranich-Bach employs a (what I call) "through the valve" method of delivery vacuum to the striker pneumatic (note bellow). Initially, when I learned that the valve gap was a very shallow 0.020", I thought, 'How can this thing work efficiently?'. Then it dawned on me that the vacuum doesn't pass around a valve facing and through the gap to reach the bellow. It passes right through the opening. So, that started me to thinking about the square area of the air gap in a 'common' system verses the square area of the 'through the valve' system. Using some fairly common figures, I started doing the math. Let's say the size of the intake valve port is 1/2" and the gap is 0.035". The total square area through which air can pass is the circumference of the 1/2" hole (C = 2 ⋅ π ⋅ r), or 1.571", times the gap (0.035"), or 0.055 sq. in. Now, looking at the Kranich-Bach valve facing, you have an I.D. of 0.425" with a crossbar that's 0.135" wide. (see Fig 3.1) So, doing some simple math, we have the square area of a circle (A = π ⋅ r2), or 3.1417 x (0.2125" x 0.215") = 0.1418 sq. in. minus the area of (basically) a rectangle measuring 0.135" x 0.425", or 0.0574 sq. in. That leaves us with a total square area through which the vacuum can pass of 0.0844 sq. in. As you can see, even if the hole in the Kranich-Bach valve was smaller, the area through which the air can pass is still 50+% greater than with a common-type valve.

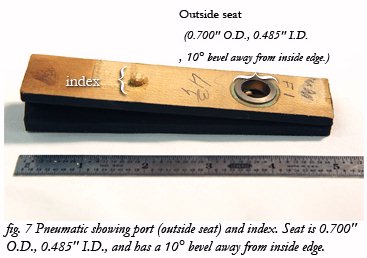

Now, concerning the narrow 0.020" valve gap, the question arises, 'Doesn't it impede performance?' Well, let's examine that. Since we have already eliminated the aspect of 'sucking' the air out of the bellows, the only thing that remains is letting the atmosphere back into the bellow. So, let's take a look at the I.D. of the (what is essentially the) exhaust valve port (which is part of the bellow). (see Fig 7) It has an I.D. of 0.485". With a gap of 0.020", the square area through which atmosphere can enter into the bellows is basically a long slit that's the circumference of the hole (C = 2 ⋅ π ⋅ r) times the gap (0.020"), or 1.52" times 0.020", which is 0.030 sq. in. Comparing that to the common valve, we see that it is 0.055 sq. in. So, based on those figures, one would have to assume that the narrow valve gap is problematic. What happens if we increase the gap to a more normal 0.035"? Then the square area is 0.053 sq. in., which is almost identical to the common valve. However, maybe we're missing one important part of the equation, and that is the size of the striker pneumatic. While there are no pictures that actually show the exact measurement of the bellows, in Fig 7 we can see that it is almost exactly 5" long and about 3/4" wide. If it's like most striker pneumatics, it has a span of 1-1/4". That equates to a working area (internally) of 1.406 cubic in. of air space. Comparing that to the size of a common striker, which measures 4" x 1-1/4" x 1-1/4", we find that the internal square area is approximately 2.125 cubic in., or just over 50% bigger. The point I'm trying to make is that it seems that the small gap is more than adequate to allow air to 'fill up' the bellows just as fast as the larger gap and a larger bellow. I admit that I don't have the math skills to figure these things out precisely. However, in terms of performance, the ability to suck the air out of a bellows at a very fast rate seems to me to be very important because the faster you can close the bellows, the more time you have you have for it to open back up.

Disclaimer: The opinions expressed above as simply that; opinions. No scientific tests were run. However, just based on the above numbers, it seems to me that the Kranich-Back system is more than capable of performing at least as well as most other systems, if not better. Signed: John A Tuttle

On 2/24/2010 10:50 PM, Tim Geinert wrote: John, A couple of moons ago I called you asking if you knew anything of the Kranich & Bach player action. You asked me for photos, and here they are. My son did the lay-out, and I need to enlarge them a lot on my computer, but when enlarged they convey the info just as I wanted. If you need anything else, please let me know.

Tim Geinert On Feb 25, 2010, at 4:59 PM, John A Tuttle wrote:

Hi Tim, Thanks for the pictures. I split the page up into individual pictures. It will be easier to put them into a webpage.... One thing is very obvious from the pictures... Everything has to be "exactly" right. There appears to be absolutely no room for error. All the materials have to be exactly like the originals in order to set the valve gap. I suppose you could use 0.008" thin pneumatic cloth and reduce the thickness of the leather valve facings by 0.002". It certainly doesn't seem like 'a better mousetrap'. Alignment of the pneumatics is really critical... down to the thousandth of an inch. Most system are considerably more forgiving in that regard. They must have had a good jig for positioning the bellows. Thanks again for the pictures. I'll try to get a webpage put together within less than a week. Any other pictures you have will be appreciated. Musically,

John A Tuttle On 2/25/2010 11:19 PM, Tim Geinert wrote: Hey John, Glad you were able to use the photos. About the exactness. Yes it will require that. But what of the 0.020" valve clearance? I can't imagine that being correct. One way of adjusting that clearance is through the thickness of the canvas/webbing type fabric strips under the pneumatics. This fabric is in several of the pics, but shows best in figs. 1 and 8. The fabric is glued to the valve board, at both ends of the pneumatic, and the pneumatic is glued to the top of it. So, thicker fabric, wider valve gap. FWIW the pneumatics come loose from their home VERY easily, but are secure before removal. About the placement of the pneumatics...there is a dowel on the pneumatic and a hole in the valve board( I use the word "index" in the text of the photos, figs. 1 and 7)) and if the pneumatic is square, it is right. ( I think) I am getting advice from 2 gents that have locked horns with this 'better mousetrap'. I am told it is a VERY expressive player.

Tim Geinert On 2/26/2010 12:38 PM, John A Tuttle wrote: Hi Tim, I noticed the 'index' dowel after I replied... The one thing that makes it difficult to remove pneumatics from the deck is the fact that the 'air hole' in the bellow has to be well sealed. That 'problem' is eliminated in this design. It's actually quite clever. As for the valve gap, 0.020" does sound very small, but it this case, the vacuum travels through the valve to collapse the bellow. So, the gap is irrelevant. The only time air passes 'through' the gap is when the bellows is opening. And, the valve seat on the bellows has a relatively large square area. So, the air can enter into the bellows with ease. BTW, I didn't figure all this out until just now. And if you look at the square area of the holes in the valve, through with the vacuum passes to collapse the bellows, it's actually fairly large by comparison to the square area of a valve with a 0.035" gap. It would be interesting to take some very exact measurements and compare the square area of the vacuum 'ports' in the valve to the square area of a Standard type valve with a gap of 0.035" - 0.040". If my guess is right, having that larger area for the vacuum to pass into the bellows would account for the increased expression capability of the system.

John

|

| Player Piano Reference Materials - Click Here |

![]() ..To

The Top of this Page . . . . . . . . . . .

..To

The Top of this Page . . . . . . . . . . . ![]() ..To The HOME Page

..To The HOME Page

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |