|

1/1/23: We are NOT making kits at this time.

Installation Instructions

#650 Deluxe Suction Box Kit

There are a few reasons for installing this suction pump. (1) Short of complete rebuilding

of the player action, it may be expedient to defer this eventuality. (2) It may be easy to

foot-pump, but there are times when you may want to be away from the piano for a

moment. (3) Children or the elderly sometimes have difficulty foot-pumping, whereas you

don't.

Whatever the reason, the installation of this kit need not destroy the original operation or

prevent it from being returned to its original state. There is an internal check valve built

into the suction box, which is like a one-way valve. The vacuum motor can draw air from

the player action, but the connection of the suction box does not allow passage through it

when the foot-pumps are operated.

The vacuum motor used is somewhat similar to the type that would be found in a vacuum-cleaner. Since the vacuum necessary to operate a player piano is usually far less than

needed to sweep the floor, an electronic resistance control is used, so that only the actual

suction level needed will be produced. Two levels of vacuum are an important feature of

the control unit used on this suction box. During re-roll the demand for vacuum is only

about one-third as great. The pneumatic motor and controlling governor were not

originally designed to regulate an excessive amount of vacuum, which would be the case

with little being consumed, but still pumping at the same rate. With foot pumping, the

pumping strokes are at a slower pace. However, the electric motor needs to be told to

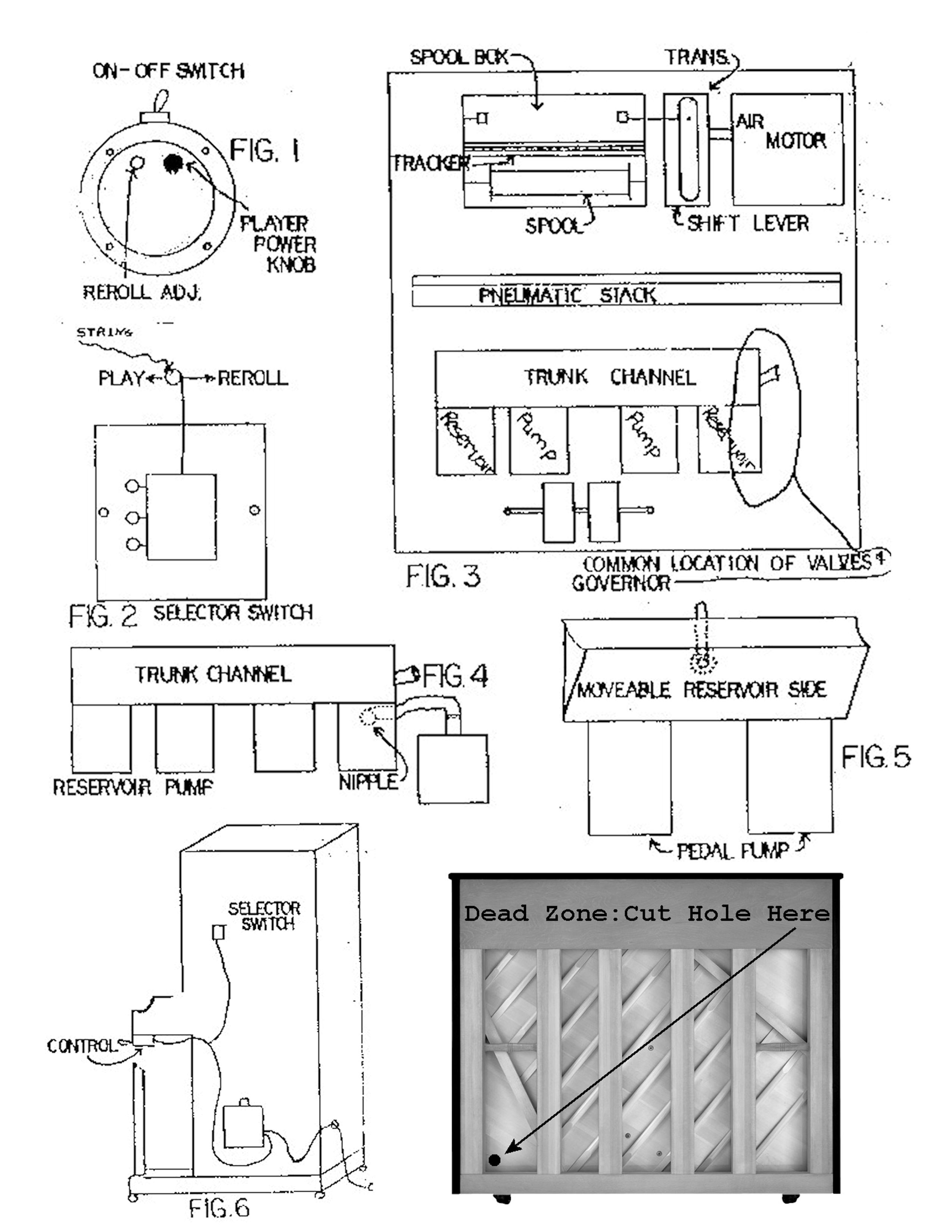

slow down, and this is why there are two speed circuits, with the selector switch (Fig. 2)

which automatically switches from the ‘Play’ speed to the ‘Rewind’ speed when the

Play/Rewind lever is moved to the Rewind position. This is accomplished by simply tying

the string to the moveable part of the Play/Re-roll linkage. The selector switch selects the

Rewind speed, which has been set up through the potentiometer on the controller (the

post without the knob).

The main thing for you, the installer of this kit, to figure out is: where to drill a one Inch

hole in the lower pump assembly to properly add the flanged fitting to connect the 1-1/4"

hose from the suction box. There were two basic types of construction (shown in Fig. 4

and 5)

Ignore the two original foot-pump bellows. These have internal check valves that

disconnect each from the vacuum system. The reduced vacuum cavity is connected to the

trunk channel and the reservoirs. Only one reservoir is needed, but most pump assemblies

have two. If only one, it is usually across the top of the two foot pumps (as in Fig. 5). In

this case it also serves as a connecting channel. You would want to drill the one inch hole

into the stationary part of the reservoir. This is easily done without removing the pump

assembly from the bottom of the piano if construction is as in Fig. 4. Usually the reservoir

in Fig. 5 has the moveable leaf facing forward, and it is necessary to completely remove

the assembly from the piano in order to drill the entry hole and affix the flanged fitting

from the back side at a convenient location.

If the bellows assembly is built like Fig. 4, but so large that there is not room for the box,

remove the right reservoir. Remove screws and break the glued stationary board of the

reservoir from the trunk channel, and patch the hole that is left. Drill a new one inch hole

adjacent to this to mount the flanged hose fitting so it is pointed down, directly over where

the suction box will be.

Normally the pedal rods go along the floor of the piano on the left side. To overcome this,

saw several scrap blocks of wood to prop up the bottom of the suction box to clear these.

A small bottle of linoleum paste and a stick to smear it with is enclosed in this kit; this is

for sticking the padding on the bottom of the suction box to what ever will support it in

position in the piano.

If you plan to run the electric cord out of the back of the piano, refer to the picture next to

Fig. 6. This is a dead zone on the soundboard, and cutting a hole here will have no effect

on the sound of the piano. Also, two extra wire nuts are included in the kit so you can cut

the electric cord near the pump box and run just the wire through the soundboard. In this

case, only a small 3/8" hole is required. This avoids making a larger hole for the plug.

Installing the Selector Switch.

The Play/Rewind lever moves rods and mechanical

linkage that do three things:

1. Shifts the transmission from the take-up spool to the music roll.

2. Operates the cut-off valve to the pneumatic stack.

3. Operates the valve that by-passes the Tempo Control and Air Motor Governor.

The Selector Switch (See Fig. 2) can be installed at any point on this linkage where a

string can be attached between it and the Selector Switch lever. Note that the switch lever

must be pulled to the left when the Play/Rewind lever is in the Play position, and released

when it is in the Rewind position. (Under the key bed or by the transmission usually works

best.) The switch is spring-loaded to the Rewind position. So, when the tension on the

string is released, the switch returns to the Rewind position automatically. Although there

is about a foot of string attached to the lever, it is recommended that you only use what’s

needed and discard the rest.

A convenient location for this switch is by the air motor at the right of the transmission.

With the transmission in the Play position, tie the string to the bottom of the shift lever

(in most cases) so that it pulls the Selector Switch lever fully from its at rest position.

The electric cord to this switch is long enough to reach from the lower part of the piano to

this location, around the right end of the pneumatic stack. Extra wire can be coiled up and

stowed. A connecting plug is provided so the switch can remain in position when the

upper action is removed for servicing or tuning.

Mounting the controller (shown in Fig. 1) Fig. 6. shows complete installing of the wiring.

The dual-speed electronic controller is mounted on the bottom of the key bed and to the

side, so that it will be out of the way for foot pumping. The on-off switch and playing

power knob can easily be operated even though it is out of sight. The power cord to the

wall receptacle is brought out the back of the piano, behind the suction box by drilling a

hole through the soundboard. This will have no effect on the sound of the piano.

It is a good idea after installation to place a cloth strainer over the fitting on the suction

box and slip the hose over it to catch any sawdust or shavings that might come through

during the first several minutes of running. Air is drawn directly through the motor to cool

it, and dirt must not be allowed to enter.

Avoid running the suction box with the Intake completely closed because this robs the

motor of the air needed to keep it cool. Under normal usage, enough air passes through

the motor to cool it. Even though the exhaust air can get a little hot, the fact that you can

feel the moving air shows that air is passing through.

General Information: If you have problems, send an email to johnatuttle@gmail.com, or

phone (732) 840-8787, or write Player-Care, 407 19th Ave., Brick, NJ, 08724. You will

probably never need replacement parts or repair, but if you do, contact me.

If you need extra 1-1/4" vacuum hose to connect to a top Installation, the stock no. is 551.

This sells by the running foot and is available from Player-Care or could be obtained from

your local vacuum-cleaner repair shop. In a very few cases, due to the construction of the

original lower pump assembly, there is no way to remove part of it to make room for the

addition of the suction box in a very practical way. In this infrequent situation, it is

suggested that the upper left corner of the piano case (between the lid, above the piano

hammers) be cleared. Use a hinge to attach the bottom of the box flush with top of the

piano side. In this manner, the suction box may have the hose disconnected and simply

swung outside the piano case when the piano is tuned. For this situation, it will require an

extra length of hose.

In setting the right amount of vacuum for the Rewind mode, it is suggested that you play

out the longest music roll you have. Stop at the end. Turn the potentiometer post (Fig. 1.)

without knob, all the way counter-clockwise, Put tempo lever at zero, shift gears to Re-wind. Turn suction box back on and turn this post clockwise until the roll barely starts to

move. This will set the minimum speed when it can start re-rolling from a dead stop.

Conditions may change. Lower humidity conditions such as found in a heated home during

the Winter may open up some new leaks in the player system. Especially one that has not

been rebuilt and resealed. During this season the Rewind circuit may have to be reset.

This suction box kit has a lot of reserve power. Up to 70+ inches of water lift vacuum.

This can overcome a lot of leaks and still be able to play loud when you want it to. There

will be a varying degree of permanent leakage in the system, but once this is overcome,

the additional amount of vacuum required to play from very soft to very loud, will

probably vary from 20 to 50 inches of vacuum.

Also, many people enjoy their player piano more when they pump the pedals. As

mentioned previously, this feature will not be disturbed by the installation of this kit. But,

what most people don’t know is that the ‘Play’ control setting can be adjusted in such a

manner that it will only compensate for the leakage in your system. To accomplish this,

put a roll on and start the electric vacuum pump. Adjust the Play control setting down to a

setting such that the music is just barely playing. Then start using the foot pedals. The

recommendation is to set the volume of the music as low as possible so that all of the

notes still articulate correctly. Then when you pedal, you can add expression to the music

by pumping just a little harder at the appropriate moments. It adds a whole new dimension

to the music that you’re sure to enjoy.

This set of installation instructions is also shared with the Deluxe Full Automation Suction

Box Kit. The same controller is used in both systems. Therefore, there are effectively two

‘On-Off’ switches. ‘One’ on the controller, which should be left in the ‘On’ position all of

the time, and ‘Two’ the one on the Automatic 'Off' / Pushbutton 'On' Device. The

automatic shut-off device mounts in the spool box and responds to the flipping tab of a

roll that is fully rewound, to shut off the suction box. However, the ‘On-Off’ switch on the

controller can be used at anytime to turn the vacuum pump ‘Off’, should that become

necessary.

The electrification of the player piano should not affect the tempo setting, but now would

be a good time to check it out.

The Player-Care 88-note test roll, is now available at Player-Care.com for slightly more

than the price of a standard size music roll. The roll has the Tempo Test scaled on it.

However, if you do not have one, use a ruler on one of your existing music rolls to mark a

starting and ending mark seven feet apart. The graduations on the tempo indicator are 10

for each foot of travel per minute. That is, with tempo set at normal "70", it should take

one minute to travel from start to end of the seven foot mark (or half minute for a 3-1/2 ft.

increment. Adjustments can be made on the indicator needle by trial and error,

accordingly. However, it is much better to make adjustments to the Air Motor Governor

(AMG). To access directions for adjusting the AMG, go to the web page at:

https://www.player-care.com/test_me.html

The Test Roll also has a Repetition Test, a Capacity Test, and a Scale Uniformity Test.

The roll is available at: https://www.player-care.com/testroll.html

After a player is electrified, it usually directs the thinking toward acquiring music rolls that

have an LP playing time, such as several tunes on one roll, or large medley rolls. Q-R-S

music rolls produces a large variety of these, show tunes and others, and may begin

issuing new ones in the not-to-distant future. For a free copy of the Q-R-S Music roll

catalog, call QRS at 1-800-247-6557. Player-Care also carries a wide selection of

technical literature and rebuilding supplies.

There has never been a request to supply the motor brush replacements, so perhaps they

just don't wear out. We do know that the slower running motor speed allowed by the

electronic control greatly increases the life, as opposed to running full blast as in a

vacuum-cleaner application. Regardless, there is a five-year guarantee on the vacuum

pump and a one-year guarantee on all other parts. If a part or device fails, any attempt to

repair it will void the guarantee. Send it to Player-Care, 407 19th Ave., Brick, NJ, 08724, or send an email to John A Tuttle - johnatuttle@gmail.com for instructions.

|