|

|

|

|

|

|

| Home | Manuals | Supplies | Search | Consult | Contact | Testing | Service |

Technical Manuals .. (click here) Test your 'Player'.. (click here)

|

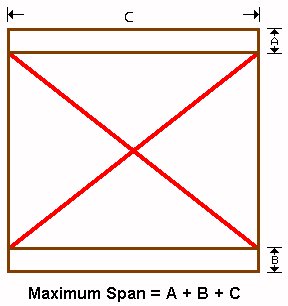

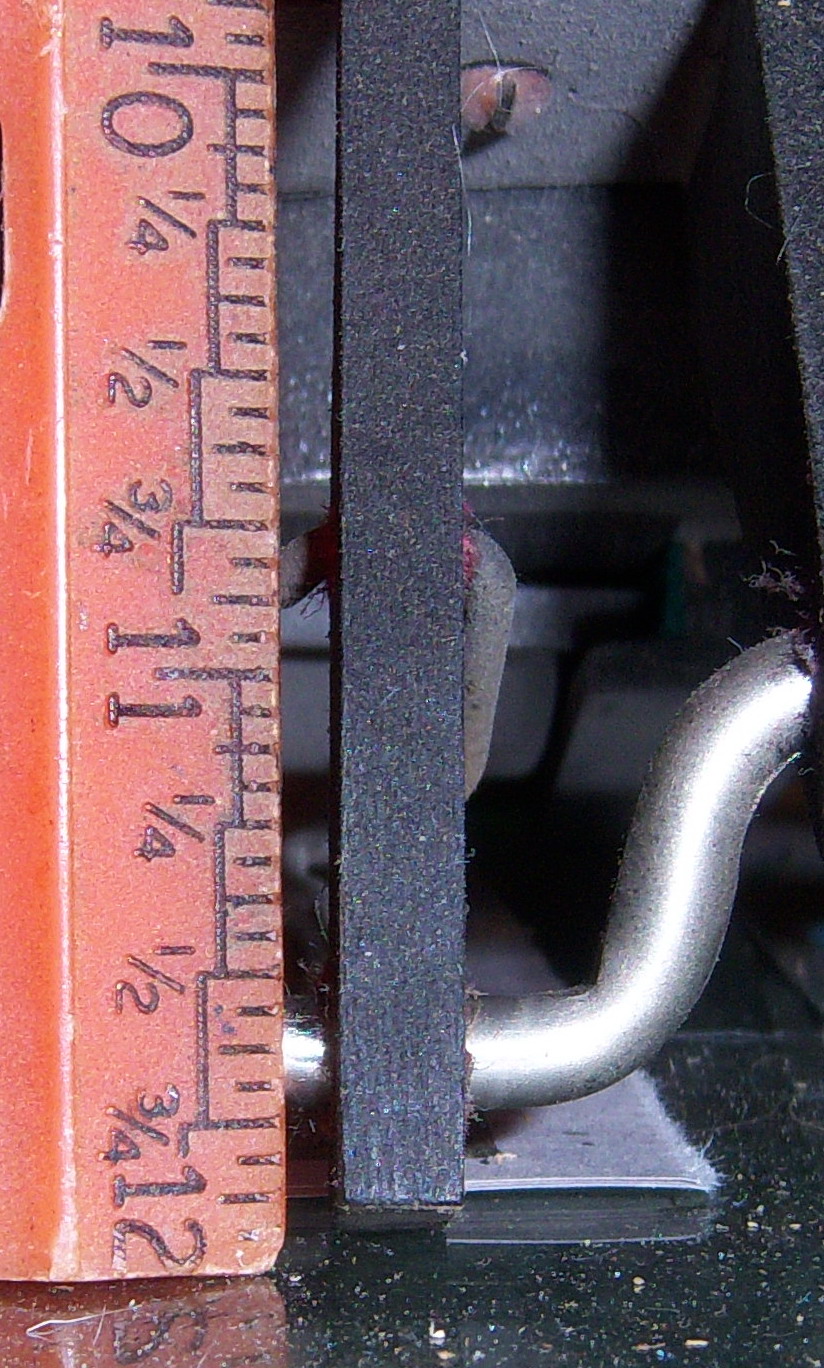

Since there are so many different player system manufacturers, and considering that none of them ever listed the amounts or types of pneumatic cloth that they used, you have to figure it out for yourself. However, this is not a difficult task. We'll start with the heaviest cloth, then the medium weight cloth, and then we'll move on from there to the thinnest cloth. All cloth, regardless of its thickness, is sold by the 'running yard' or 'running foot'. A running yard measures 58"-60" wide by 36" long. A running foot measures 58"-60" wide by 12" long. (Heavy cloth is also sold in strips that measure 6" x 60".) Listed below are the various devices found in a normal 88-note player piano. The various highlighted terms are linked to definitions. Generally speaking, all bellows are made the same way. One continuous piece of cloth is wrapped all the way around the perimeter of the bellows, and the ends of the cloth overlap on the hinged end of the bellow. The amount of overlap varies depending on the size of the bellow. But, as a general rule, the overlap is approximately 1/2 to 2/3 of the width of the bellows board. All bellows open a certain maximum number of inches (see Special Note below). The measurement of a bellows when it is fully open is called the 'span'. So, with regards to the bellows cloth, every bellows has two important measurements; the span, and the perimeter. Typically, the heavy weight cloth is only used for the Exhausters and the Reservoirs. The average exhauster measures 15" X 12" and, therefore, has a perimeter of 54". The average span of an exhauster bellows is 6" or less. The average reservoir is usually slightly smaller than the exhauster if there are two reservoirs. If there is only one reservoir, it is always larger than the exhauster. Usually, there is a minimum of a three-inch overlap for both the exhauster and reservoir bellows. So don't forget to figure that into the total. For larger bellows, consider covering them with two pieces of cloth as per the left and center graphics in this picture.. click here. The width of a bolt of heavy bellows cloth is 60". The typical player piano will require two running feet of cloth. That's a piece of cloth that's 60" x 24". NOTE: The best glue for gluing heavy cloth to wood is animal hide glue, but 'plastic glue' can also be used (not recommended -see why). Typically, the medium weight cloth (or Peripheral Devices Cloth) is used for the air-motor (or wind motor), air-motor governor (or governor), the roll tracking mechanism (or tracker), the auto-sustain, and other peripheral devices like the Bass and Treble Soft pneumatics and any other 'control' devices. Generally speaking, this cloth is for medium size bellows with a perimeter of 15"-25". The perimeter and span measurements for the above named devices varies to such an extent from manufacturer to manufacturer that it is impossible to quote any meaningful averages. The only way to insure that you purchase enough cloth to do the job is to measure each device separately. The width of a bolt of medium weight cloth is 57"-60". The typical player piano will require about one running foot of cloth. That's a piece of cloth that's 60" x 12". Note: the correct glue for gluing nylon cloth to wood is 'plastic glue'. . Finally we come to the thinnest cloth (or striker pneumatic cloth). This cloth is usually only used for the small striker pneumatics (or note bellows) that activate each of the notes of the piano action. However, some manufacturers also used this cloth for air-motors and other small-to-medium size bellows. When in doubt, use a micrometer and measure the thickness of the original cloth. The striker cloth that was used in player pianos for over 100 years was about 0.008" thick. That rubberized cotton-backed cloth is now available -click here. Also available for striker pneumatics is the increasingly popular nylon striker cloth, which is 0.004"-0.005" thick. The 'width' of the bolt of both the cotton-backed striker cloth and the nylon striker cloth is 60". The typical player piano requires no more than one yard of the cloth, and we refer to the yard as the 'length' of the cloth. To see a graphic of how to get the most strips out of a yard of cloth, click here. Note: the correct glue for gluing nylon cloth to wood is 'plastic glue'. ALSO NOTE: As of 2020, the cotton-backed striker pneumatic cloth is 56" wide, not 60". For the Record: With regards to cutting strips of thin cloth, we do not recommend ripping the cloth. It does not rip in a straight line across the 'width' of the bolt, which is 56"-60". What's important is to draw out a plan in accordance with your needs BEFORE you start cutting the cloth. Also take note that ALL bellows cloth has a bias (See YouTube video -click here) and Wikipedia webpage -click here. While not absolutely necessary, most professionals agree that bellows should be constructed such that the cloth doesn't stretch across that span of the bellow. . Special Note: People often ask me how to determine the correct span of a bellows if the cloth is missing or ripped. While it is somewhat difficult to figure out the minimum required span, it is easy to ascertain the maximum allowable span*. (See Note below.) The rationale for this formula is that if the span is any wider than prescribed below, the opposing sides of the cloth will touch each other when the bellows collapses. If that happens, the cloth will wear out faster because of the friction created when the two pieces of cloth rub against each other.

*Note: The only exception to the above 'rule of thumb' involves bellows that are folded as seen below. However, it should also be noted that bellows folded in such a fashion are always limited by some other factor so that the opposing edges never touch each other.

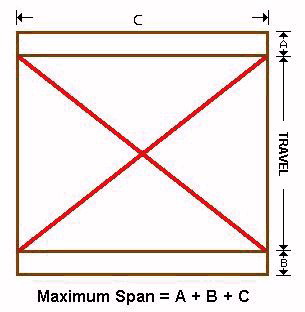

. As a general guideline, the minimum required span for any bellows (that's used to control the operation of a mechanical function, i.e., tracker, sustain, bass/treble soft, auto-rewind, piano action, etc.), is determined primarily by the operating distance that the device must 'travel' from the 'On' position to the 'Off' position plus 25%. In other words, if the component being moved by the bellows must 'travel' a distance of 1" (one inch), the minimum 'travel' of the bellows must be 1-1/4". Do not confuse "travel" with "span". As explained previously, the 'span' of the bellows includes the thickness of the two pieces of wood. The 'travel' is the space "between" the boards. So, as seen below, SPAN = TRAVEL + A + B

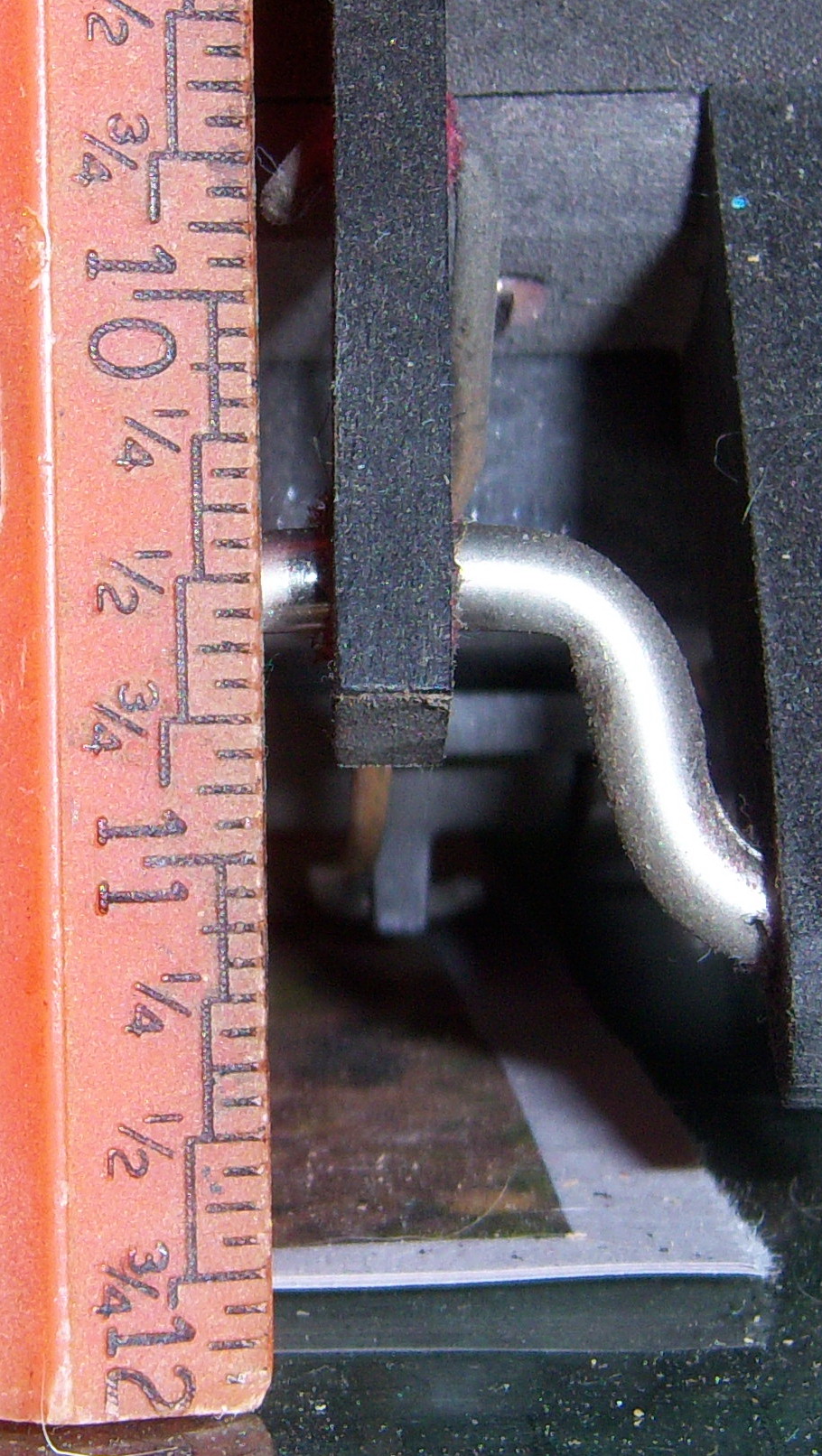

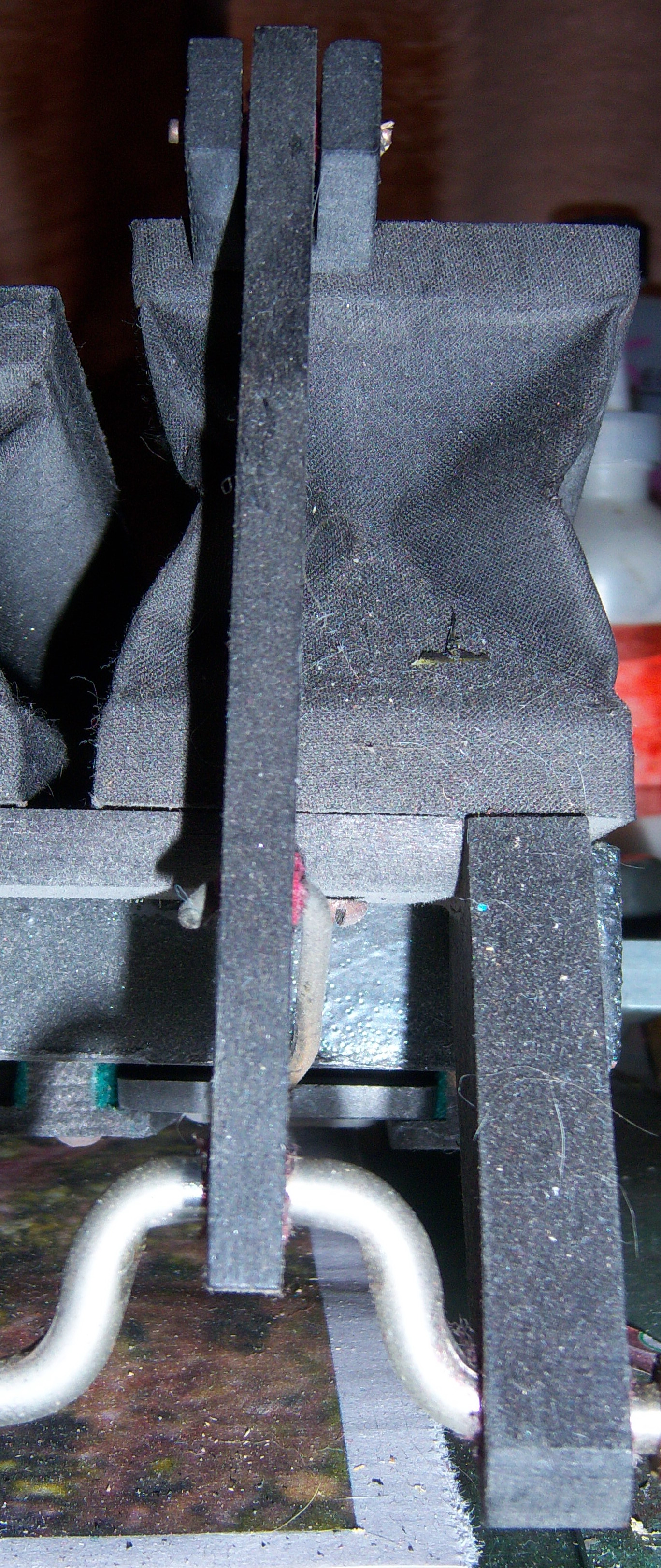

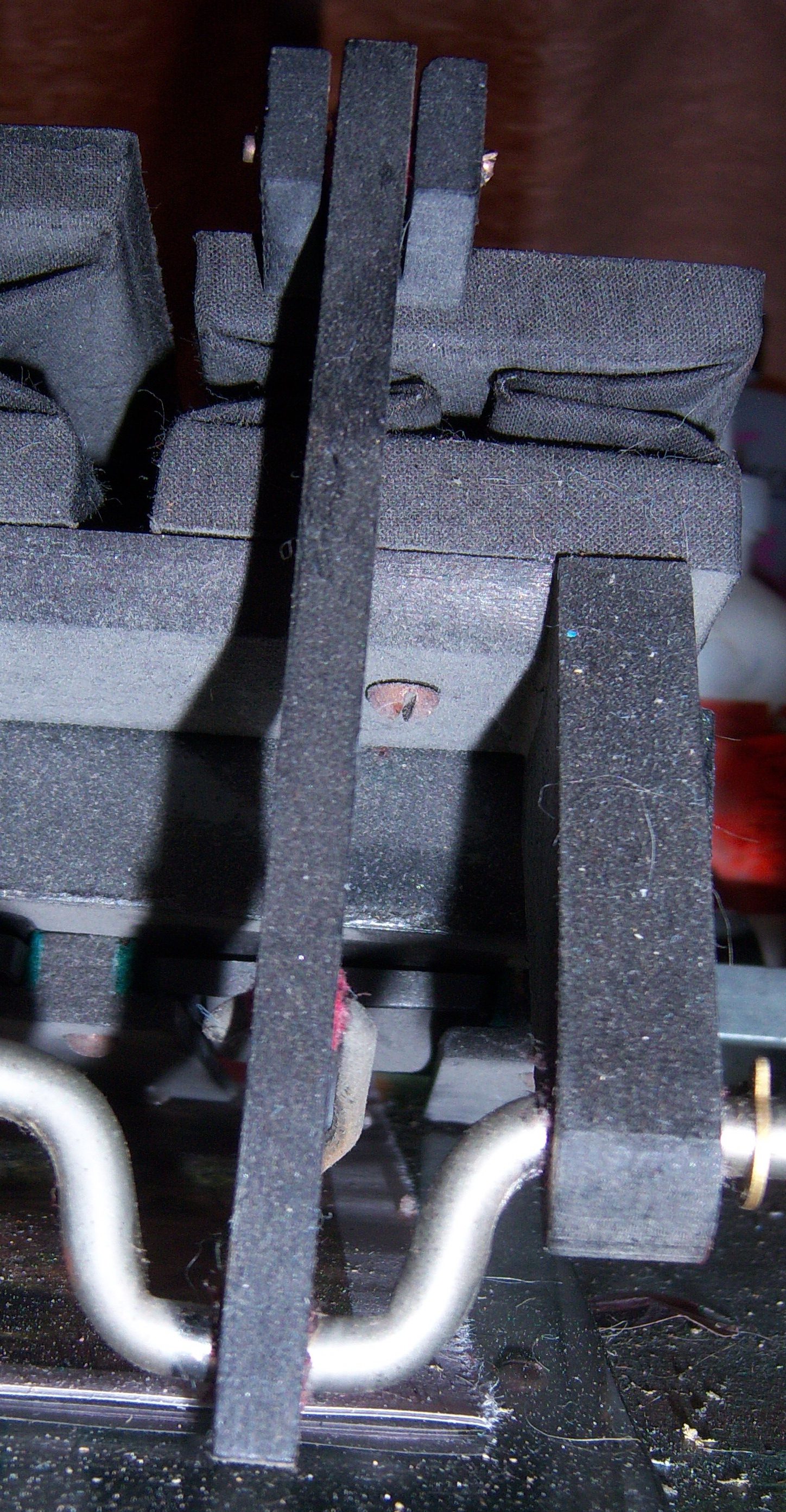

. When dealing with Air Motors, the important thing to keep in mind is that you want to operate the bellows "within the area of least resistance". And while that is a basic truth for all bellows, it's critical when it comes to air motors because if any of the bellows in the motor has any resistance to movement within the area of operation, the motor will NOT run smoothly. For this reason, the span of an air motor bellows is typically around 35% more than the actual 'area of operation', or the distance the bellows travels from open to closed while it's working. So, a bellows that requires a 'Traveling distance' of 1-3/16" will require a total travel of 1-3/4" to work efficiently. Generally speaking, the best rule of thumb, in this case, is to err on the side of too large of a span instead of too little. As well as showing how the travel is measured, the pictures below show what an air motor bellows should look like in operation when the cam is at its two extremes.

|

This page was last revised on December 18, 2024.

|

Since "Player-Care" is an internet business, I prefer that we correspond via E-Mail (click here to fill out the 'Request Form'). However, if I'm not in the middle of some other activity, you can reach me at 732-840-8787. But please understand that during the hours from 8AM-5PM EST (Mon-Sat), I'm generally quite busy. So, I probably won't answer the phone. If you get the answering machine, please leave a detailed message stating the reason for your call. Also, repeat your name and phone number clearly and distinctly. By necessity, I prioritize everything in my life. And, if you call and just leave your name and number, and ask me to call you back, it might be a day or two before I return your call. Why? Because I don't know why you want me to call and I might not be prepared to assist you in an effective and efficient manner. If you leave me an E-Mail address (which I prefer), spell it out phonetically. The more you do to help me, the more I can help you in return. Don't rush. You have four minutes to record your message. |

|

407 19th Ave, Brick, NJ, 08724 Phone Number 732-840-8787 (Voicemail Only, No Texts) |